SCI Analytical manufactures a wide variety of custom specialty gas mixtures. Our specialty gases are used in several fields such as laboratories, research and development, universities, healthcare, and utilities.

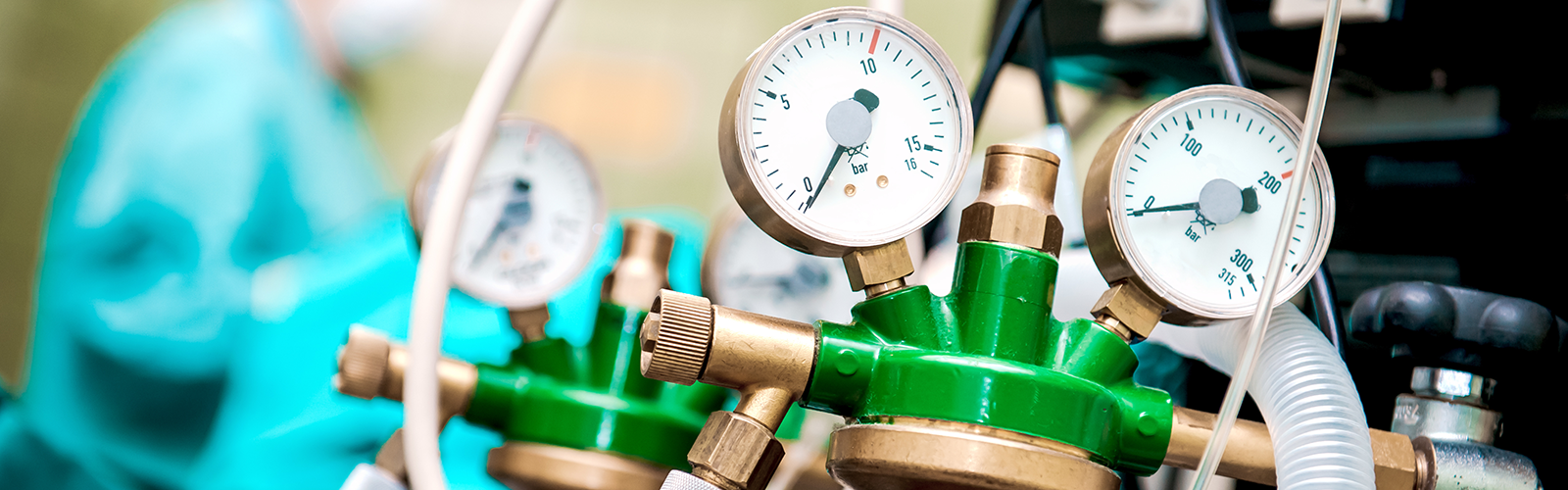

The manufacturing of specialty gas mixtures begins with the cylinder delivery system. Preparation of cylinders and surface treatment of the cylinders are imperative to providing quality custom gases. It is critical that the cylinder preparation be individualized based on each specialty gas mixture. SCI Analytical has a broad range of cylinder sizes available for any application and each cylinder is prepared based on the specifications of each individual specialty gas. Cylinder treatment processes should have shelf-life data to prove the quality of their gas mixtures. Many reactive chemicals, even at minute concentrations can drastically affect the quality and accuracy of the mixture. Some examples of reactive chemicals include nitric oxide, ammonia, hydrogen chloride, nitrogen dioxide, and hydrogen sulfide.

The next step in the process is the blending of the specialty gas. First, the manufacturer must analyze the purity of the raw materials that will be used to create the custom gas mixture. Computer modeling is then used to calculate phase behavior for the gas mixture before the blending process begins.

There are three main methods for blending specialty gases: gravimetric, volumetric, and dynamic blending. The most precise of these methods is gravimetric blending.

Gravimetric blending is used for applications needing high accuracy and tight blend tolerances. The specialty gas mixtures are created to the exact specifications utilizing gravimetric scales which are highly sensitive. The resulting gas mixture is then rigorously analyzed to ensure that the stated values are accurate.

The manufacturing process must be carefully monitored and measured along the way. Beginning with the proper selection and preparation of the cylinders used, then the analysis of the raw materials and phase behavior calculations, through the measurement of the gravimetric b

lending. Strict quality control and thorough analysis throughout the manufacturing process ensures an accurate, quality custom specialty gas.

The use ofraw materials with contaminants or failure to carefully monitor the production process leads to sub-par mixtures. At SCI Analytical, we ensure that every step of our manufacturing process is analyzed for accuracy. From our cylinder preparation, to our raw materials, and throughout our manufacturing process. We work hard to ensure that the custom specialty gas mixtures we deliver are of the finest quality and accuracy available.

The filling technique is also very crucial to providing a quality product. There are new updates and filling techniques on the market each day and it is important that the manufacturer be up to date on the latest technology. SCI Analytical is always researching new filling techniques to ensure we are delivering the most accurate specialty gases available.

SCI Analytical utilizes the finest materials, manufacturing processes, and filling techniques to provide our customers with the most accurate custom specialty gases on the market. We deliver only the finest quality gas mixtures to our customers worldwide. It is our commitment to quality and customer service that makes SCI Analytical the best provider of custom specialty gas mixtures in the marketplace.